Author: Ir. Dr. Justin LAI Woon Fatt | 29 Sept, 2022

WHAT IS CORROSION OF STEEL REINFORCEMENT IN CONCRETE?

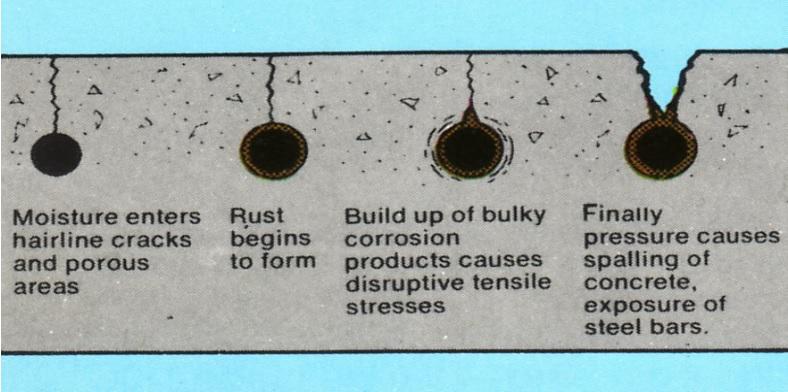

Steel corrosion is defined as the process of degradation of steel reinforcement caused by the chemical reaction in concrete due to environmental action. When steel reacts with water or chloride, chemical reaction will occur, resulting in the formation of a film of scale around the steel bar, known as rust. As the consequence of the progressive formation of rust over time, the volume of steel reinforcement increases and internal stress will be generated in the concrete, causing cracking, spalling, and delamination of concrete [1]. As time goes by, the steel loses its function. Steel corrosion is a major structural problem that is often related to a serious durability concern. The rusting will occur across the entire steel bar if the steel bar is not treated effectively and promptly. Therefore, immediate action must be taken to cure the steel bar before the corrosion develops into a partial or total collapse of structure.

Figure 1: Corrosion of Steel Reinforcement in Concrete [2]

Figure 1: Corrosion of Steel Reinforcement in Concrete [2]

WHY DOES THE CORROSION HAPPEN ON STEEL REINFORCEMENT IN CONCRETE?

- Dampness of concrete

The dampness of concrete might be due to water permeability, water seepage, and water leakage. The dampness of concrete is usually higher in the toilet and basement with excessive moisture content and high humidity. When there is a formation of crack on the structure regardless of its size, there is bound to water seepage. As water penetrates the concrete structure, the dampness can lead to rusting which can weaken the concrete strength. Also, the crack may expose the reinforcing steel to the atmosphere and increase carbonation [3]. Besides, dampness occurs when there is a high water-to-cement ratio where the excess water is known as ‘free water’. The surplus moisture in the concrete can accelerate the process of rusting. Also, dampness can be caused by inappropriate design which causes the concrete structure to be exposed directly to harsh weather conditions. - Inadequacy of concrete cover

The concrete cover plays a significant role in protecting the steel reinforcement from corrosion caused by environmental effects. Inadequacy of concrete cover might be due to shoddy workmanship where insufficient spacers are used, or the reinforcement becomes displaced when concrete is poured and compacted. When the concrete cover is inadequate, it eases the entry of moisture, thus resulting in rusting. The corrosion of steel reinforcement will happen if the concrete cover is inadequate. This is due to inadequate concrete cover allowing the entry of moisture. In addition, inadequate concrete cover can speed up the process of carbonation and chlorination, especially in buildings near the sea with maximum moisture and chloride exposure. Hence, the engineer needs to identify the signs of inadequate concrete cover and design the right repairs based on environmental condition to prolong the life of reinforced concrete. - Impurities in construction water

Some examples of impurities in construction water are suspended particles, miscellaneous inorganic salt, mineral oils, sugar, and algae [4]. When water with impurities is added during concrete mixing or concrete curing, it will cause the impurities to mix with the concrete. The presence of sugar in different quantities can speed up or retard the setting of cement. The presence of algae in water reduces the bond between aggregates and cement pastes, resulting in lower concrete strength. Moreover, impurities in water might reduce the alkalinity of concrete which is important for protecting the steel reinforcement. When the alkalinity of concrete used to protect the steel reinforcement reduces, water impurities such as sulphate will lead to rusting of steel reinforcements, causing degradation of steel reinforcement and deterioration of concrete. - Attacking of chemical substance

There are various attacks of chemical substances on steel reinforcement bars. For example, carbonation and chlorination. Carbonation happens when the alkaline constituent of concrete is neutralised by carbon dioxide in the air, leading to the formation of calcium carbonate. The rebar becomes unprotected from the alkalinity of concrete in this neutralised environment. As time goes by, the carbonated surface zone reaches the depth of rebar which may initiate significant corrosion, thus causing shrinkage cracks in concrete. The presence of chloride will cause chlorination and increase the electrochemical process of steel. Chlorination will not only increase the cracks in concrete, but it will also act as the cathode, while steel acts as the anode. This produces an electrochemical process which eventually leads to rusting of reinforcing steel. As a result of these chemical attacks, the corrosion rate of steel will increase, thus leading to the degradation of steel and deterioration of concrete.

HOW IS CORROSION IMPLICATED IN STEEL REINFORCEMENT IN CONCRETE?

The continuous corrosion process of steel reinforcement can cause an adverse impact on the structural serviceability by cracking or even spalling of concrete. It might also decrease the load-bearing-capacity which could affect the structural safety. When corrosion of reinforcing steel develops significantly and the rust accumulates over time, it causes volume expansion of the steel bar and generates internal pressure on the concrete surface around the steel bar. The pressure caused by rusting steel reinforcements exerted on the concrete will lead to cracks. The more severe the corrosion, the wider the cracks will be formed, and the spalling of concrete may occur due to the loss of adhesion between concrete and steel reinforcement. It will result in the concrete forming multiple layers, scaling, and peeling off. When spalling of concrete occurs, the steel reinforcement comes into direct contact with the atmosphere. Hence, steel reinforcement will become brittle, causing snapping of steel reinforcement which often comes along with the buckling of the steel reinforcement. Without timely and effective remediation, the corroded steel reinforcement will eventually lose its original strength and the collapse of the building is inevitable.

Figure 2: Effect of Corrosion of Steel Reinforcement in Concrete [3]

Figure 2: Effect of Corrosion of Steel Reinforcement in Concrete [3]

Figure 3: Spalling of Concrete [5]

Figure 3: Spalling of Concrete [5]

HOW TO IMPLEMENT CORROSION CONTROL FOR STEEL REINFORCEMENT IN CONCRETE?

Corrosion control of steel reinforcement is crucial to prevent deterioration and failure of concrete structures. The corrosion of steel reinforcement is mostly related to environmental effects, quality of concrete as well as the quality of construction practices. As the first step of corrosion control of steel reinforcement, construction practices should be established to ensure good quality concrete. Make sure that the quality of concrete materials complies with the specified standard. Using high-quality concrete is essential to maintain proper alkaline nature to protect the steel reinforcement [3]. Moreover, the construction work should be done with good workmanship. Care should be taken when mixing, placing, and compacting the concrete to control the corrosion of steel reinforcement. Besides, it is important to ensure that there is sufficient concrete coating and concrete cover. A suitable and sufficient concrete cover can protect the steel from harmful effects such as chlorination and carbonation. Furthermore, concrete waterproofing should be done to avoid the dampness of the concrete surface and prevent or at least minimize water from seeping towards steel reinforcement.

CONCLUSION

Corrosion of steel reinforcement in concrete can lead to degradation of steel and deterioration of concrete. Advanced deterioration can result in a reduction of concrete strength, spalling of concrete, and in extreme cases, structural failure. Hence, corrosion of steel reinforcement in concrete must be taken seriously as reinforcement concrete is one of the crucial constructions that undertakes a role in supporting loads of a building structure. To prevent and reduce the corrosion of reinforcing steel in concrete, corrosion control should be implemented. Once corrosion of reinforcing steel is detected, it is necessary to find the root cause and take immediate action to treat it effectively before the situation worsens.

Ir. Dr. Justin LAI Woon Fatt

CEO/ Founder

IPM Group

References:

[1] Desai, M. (2020). Causes of Corrosion of Reinforcement Steel in Concrete. GharPedia. Retrieved on 29th Sept 2022 from https://gharpedia.com/blog/causes-of-corrosion-of-reinforcement-steel/

[2] Facilitator, C. (2021). Corrosion Protection methods for Steel Reinforcement in Concrete. Constro Facilitator. Retrieved on 29th Sept 2022 from https://www.constrofacilitator.com/corrosion-protection-methods-for-steel-reinforcement-in-concrete/

[3] Happhoadmin, H. (2020). Corrosion of Steel Reinforcement: Causes, Effects and Remedies. Happho. Retrieved on 29th Sept 2022 from https://happho.com/corrosion-steel-reinforcement-causes-effects-remedies/

[4] Neenu. (n.d.) The Constructor Building Idea. Retrieved on 29th Sept 2022 from https://theconstructor.org/concrete/effect-water-impurities-concrete-properties/17123/

[5] Madeh Izat. (n.d.). What is spalling concrete? Their causes and repair. The Contructor Building Idea. Retrieved on 29th Sept 2022 from https://theconstructor.org/practical-guide/spalling-concrete-causes-repair/26027/