Author: Ir. Dr. Justin LAI Woon Fatt | 31 August, 2023

Many clients request us to increase the permissible live load from 10kN/m2 (light storage warehouse) to 15-20kN/m2 (heavy storage warehouse) after they have bought a light warehouse. It was not an easy task to simply increase the slab capacity as the original engineer designed the structure to meet the expected live load depending on the use. In fact, no engineer will overdesign the structure unless requested by the client for future purposes. Other than that, some reason to increase slab capacity is due to heavy machines/ equipment or adding racks to store heavy stuff.

Vertical loads and lateral loads are the two types of loads in buildings and structures. Vertical loads refer to all loads that are acting in the gravity direction, i.e., downward. On the other hand, lateral loads refer to the loads that act on the building or structure horizontally, i.e., sideward. Examples of vertical loads are dead loads and live loads while wind loads are lateral loads commonly experienced by buildings and standing structures. Dead loads are the permanent loads that are always present on the structure. Dead loads include the self-weight of walls, floor beams, columns, and the permanent fixtures attached or connected to the structure. Loads that are experienced by floors and roofs on a temporary basis are considered live loads. This includes the loads of moving people, furniture, machines, and equipment. Wind load as suggested by its name, is the horizontal load experienced by the structure due to the blowing wind. Wind load is more critical for tall slender structures as it can cause excessive deflection or even overturn the structure in extreme cases.

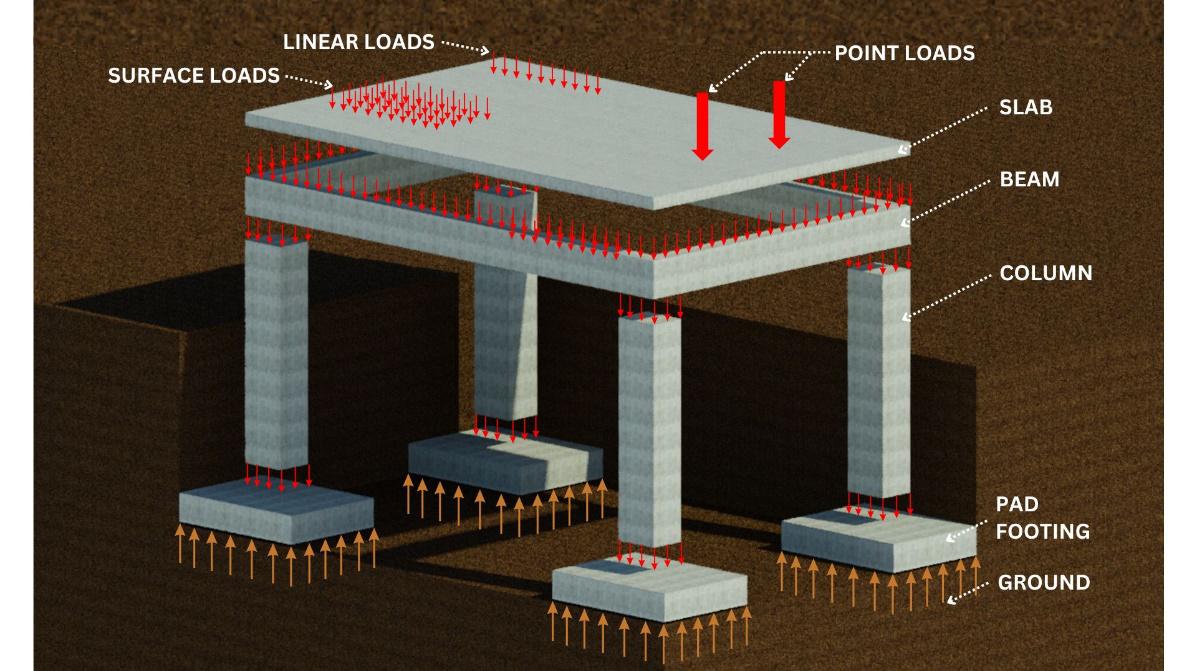

In some cases, client intended to increase the usage capacity of the slab, e.g. upgrading from a light storage warehouse to a heavy storage warehouse. In such cases, most probably the existing structural members, i.e. slab, beam, column, and foundation are not adequate to cater the additional loads, if no extra provision capacity was allocated during the design stage of the building. Strengthening of the structures is anticipated to support the additional loads. It is important to highlight that the strengthening of the slab alone is not sufficient to support the additional loads, strengthening of other structural members, i.e. column, beam, and foundation are also required due to the load transfer as illustrated in the following figure.

Figure 1: Load transfer from structural elements to the ground through footing

Figure 1: Load transfer from structural elements to the ground through footing

The load path from the structural slab to the foundation is shown on the diagram. In the design concept of reinforced concrete structures, floor loads are usually transferred from slab to beams, and from beams, the loads are transferred to the columns. Ultimately, the column transfers the superstructure loads to the foundation which supports the structure. Thus, other structural elements need to be strengthened as well if the slab element intends to take more additional loads.

One of the examples of slab and beam strengthening work is fiber reinforced polymer (FRP). Prefabricated FRP elements are generally stiff and unable to be bent to wrap around beams on-site. The most common FRP systems for concrete strengthening applications are carbon fiber based (CFRP), due to their high mechanical properties, high tensile strength, high stiffness, and good durability [1]. Prefabricated CFRP bars and plates are normally used on surfaces that are straight or minimally curved, such as the top or bottom side of slabs and beams [1].

For the foundation system, we can convert the non-suspended slab into raft pile foundation by increasing the slab thickness/ reinforcement and merging it with piles. Here are the procedures to verify the structural element if strengthening work is required.

- To study and understand the as-built structural drawings (RC structure/ steel structure);

- To perform structural modeling and verification to obtain the maximum structural capacity of each structural component;

- To compare the initial structural capacity with the new structural capacity of each structural component due to additional live loads;

- To verify if the strengthening work on the superstructure/ substructure is required.

In conclusion, it is possible to increase slab capacity, however we need to verify the structural components of entire structures if strengthening work is required. The cost of strengthening work is also an important factor to be considered if a client intends to upgrade a light storage warehouse to a heavy storage warehouse. In some cases, a newly built structure could be less costly than a strengthening structure. Thus, a structural investigation and study by a competent structural engineer are necessary for the preliminary stage before deciding to proceed with any strengthening work.

Ir. Dr. Justin LAI Woon Fatt

CEO/ Founder

IPM Group

Reference:

[1] Tarek.A (2015). Strengthening of concrete structures using FRP composites. Retrieved on 31st August 2023 from https://www.structuremag.org/?p=8643