Author: Ir. Dr. Justin LAI Woon Fatt | 28 December, 2023

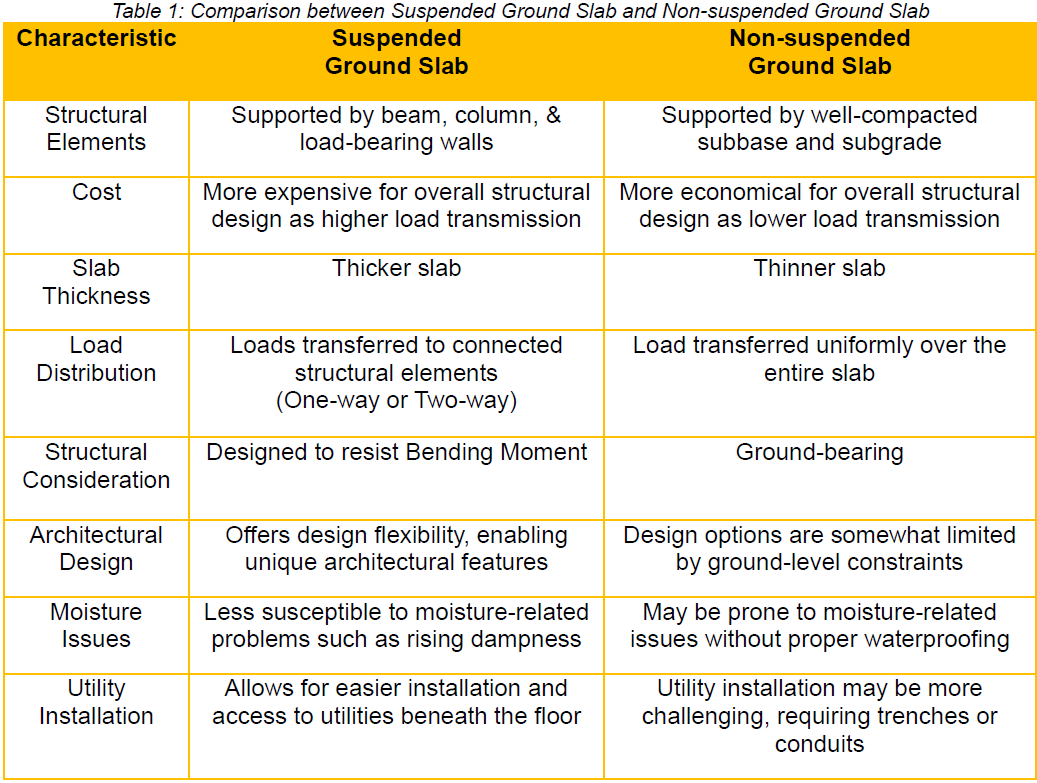

This article aims to thoroughly explore and compare the suspended ground slab and non-suspended ground slab which are the most frequently used in building construction.

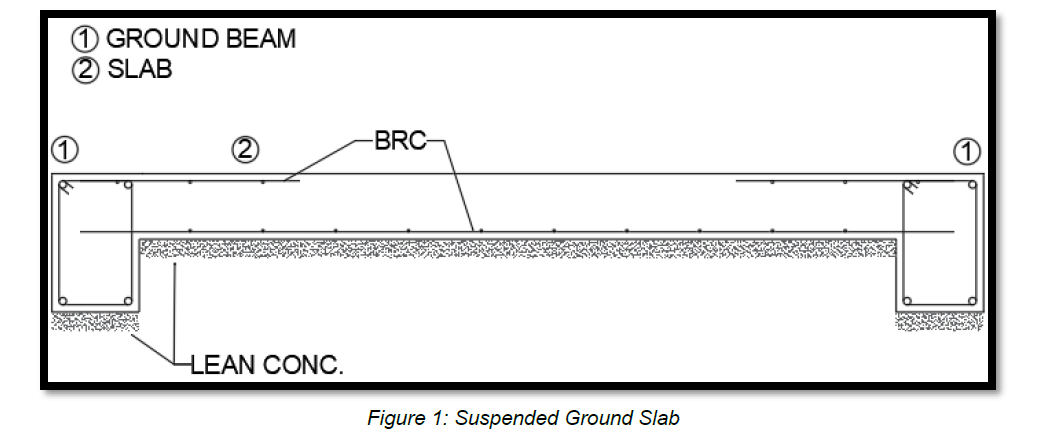

Suspended ground slab:

Suspended ground slab is a floor system that relies on connected structural elements like columns, beams, and walls to transmit loads. As the load transmission of a slab relies solely upon the supporting elements, it is crucial to analyse the load types (dead load & live load), load transfer (one-way or two-way), and load-bearing capacity of the supporting elements for structure safety, durability, and overloading prevention [1].

Non-suspended ground slab (slab-on-grade):

In contrast, non-suspended ground slabs are floor systems that cast right onto the ground, to be precise: “slab-on-grade”. The non-suspended slab is favourable as it offers a practical and cost-effective solution in building construction. It also provides easy accessibility and efficient load distributions as it rests directly on the ground [2].

The subgrade must be well-compacted and have sufficient bearing capacity to support the weight of slab and any anticipated loads without excessive settlement [3].

APPLICATIONS

Suspended ground slab:

Suspended slab is ideal for flood-prone areas as it elevates the structure above flood level [4]. Suspended slab is often utilised by architects to achieve unique and pleasing architectural designs. In cases where the construction site has uneven or sloping terrain, suspended slabs provide a level and stable foundation, eliminating the need for extensive earthworks.

Suspended slab can also be cast directly onto the ground under condition that the soil bearing capacity is not satisfying, and the project requires no gap between ground and slab.

Non-suspended ground slab:

Non-suspended slabs can be used in a variety of industries. They provide a cost-effective foundation option of various sizes in the context of residential buildings. These slabs are important in commercial and industrial buildings as they offer reliable support for large machinery and loads in factories and warehouses [5]. In the context of public buildings and institutions, such as schools and hospitals, non-suspended slabs ensure accessibility and adaptability to diverse requirements.

CONSTRUCTION PROCESS

Suspended ground slab:

Suspended requires formwork to be erected in the perimeter of the slab. The reinforcement of suspended slab is installed and connected to beam reinforcement for load transfer. Hence, the beam and slab will be cast at once ensuring structural integrity. Suspended slab requires two layers of BRC to control crack-widths and increase load capacities [6].

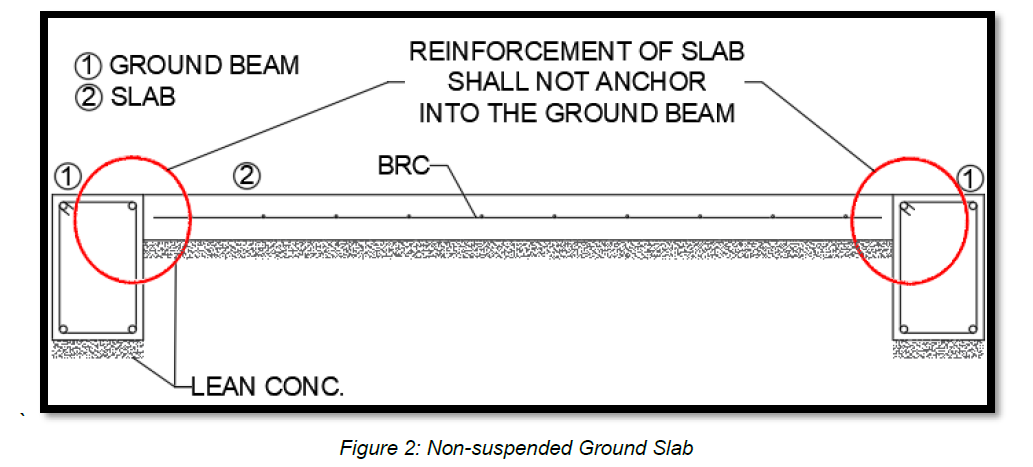

Non-suspended ground slab:

Non-suspended slab is cast separately from the ground beams. Compaction is crucial for the hardcore layer (subbase) and subgrade layer to form a firm base. The reinforcement of non-suspended slab is not connected to any other structural element as it only requires a subgrade to carry its load.

Non-suspended slab usually requires only a single layer of BRC as the slab is ground-bearing and there will be no bending moment at the supports (beam). In some occasions where the slab carries heavier loads, a double layer of BRC has to be installed as it increases the flexural or bending strength of the slab [6].

The installation of expansion joints is crucial for non-suspended ground slabs as they accommodate the movement of the concrete caused by temperature fluctuations and other factors, prevent cracking, and help maintain the structural integrity as well as the appearance of the slab over time [7].

CONCLUSION

In conclusion, non-suspended and suspended ground slabs each offer distinct advantages in construction. Suspended slabs excel in structural performance while non-suspended slabs provide cost-effective ground-level foundations. The choice depends on project requirements, showcasing the balance of practicality, design, and construction cost.

Ir. Dr. Justin LAI Woon Fatt

CEO/ Founder

IPM Group

References:

[1] Neenu S.K (n.d.). Everything You Need to Know about Concrete Slabs in Building Construction. The Constructor. Retrieved on 28th Dec 2023 from https://theconstructor.org/building/concrete-slabs-building-construction/262046/

[2] Ubani Obinna (2022, May 17). Design of Industrial Ground Floor Slab. The Constructor. Retrieved on 28th Dec 2023 from

https://structville.com/design-of-industrial-ground-floor-slabs

[3] BHA Construction Ltd (n.d.). Concrete Floor, Slabs. House Build. Retrieved on 28th Dec 2023 from

https://www.housebuild.com/construction/building-guidelines/substructure/concrete-floors-slabs

[4] CIRIA (2003, May 22). Improving the Flood Resistance of your Home. Retrieved on 28th Dec 2023 from http://www.ciria.com/flooding/pdf/CIRIA_Advice_sheet_6.pdf

[5] ydsdevreocrete (2021, Feb 18). 5 Advantages of Reinforced Concrete Flooring. REOCRETE. Retrieved on 28th Dec 2023 from https://www.reocrete.com.au/5-advantages-of-reinforced-concrete-flooring/

[6] Kim Basham (2020, May 21). How to Reinforce Concrete Slab on Ground to Control Cracking. For Construction Pros. Retrieved on 28th Dec 2023 from https://www.forconstructionpros.com/concrete/equipment-products/rebar-accessories-equipment/article/10116892/kb-engineering-llc-how-to-reinforce-concrete-slab-on-ground-to-control-cracking

[7] Fasi Ur Rahman (n.d.). Expansion Joint in Concrete – Types and Characteristics. The Constructor. Retrieved on 28th Dec 2023 from https://theconstructor.org/concrete/expansion-joint-concrete/25161/