Author: Ir. Dr. Justin LAI Woon Fatt | 31 March, 2023

INTRODUCTION

Nowadays, standard methods of problem-solving have been widely used. For instance, to build a road from point A to point B, and in between it passes a river, a standard type of bridge will be the solution. If the method has been successfully used for many times, engineers will tend to duplicate it for other similar problems. However, sometimes the standard method is not the best solution for the problem and that’s why the idea of value engineering becomes more and more important.

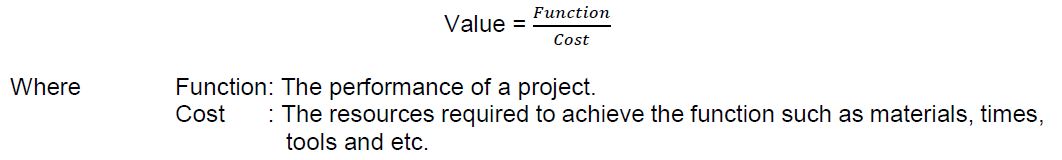

Value engineering is a systematic way to improve the value of a project. In the context of value engineering, value is determined by two main factors which are function and cost. If one increases the function or reduces the cost of a project, the value of the project will be enhanced. The relation between value, function, and cost is shown below:

THE DIFFERENCES BETWEEN VALUE ENGINEERING AND COST REDUCTION

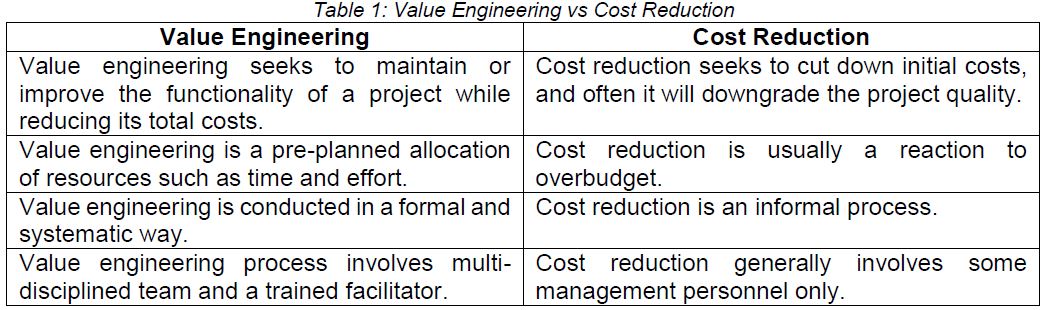

Value engineering and cost reduction are two different techniques that are applicable during the design phase of the new/ existing project [1].

Value engineering is typically used to enhance the value of a project while still meeting the required levels of quality. It can be done by reducing the number of materials needed, shortening the time frame to build a project, or finding cheaper alternatives to high-cost items.

On the other side, cost reduction is a method for cutting down project costs and may compromise the project’s quality. It can be done by using cheaper materials whenever and wherever possible and reducing the amount of labour needed.

The differences between value engineering and cost reduction are summarized in the table below:

BENEFITS OF VALUE ENGINEERING

The benefits associated with value engineering include [2]:

- Cost Reduction

The main reason this technique is utilised in the construction sector is that it helps to cut costs and optimise the budget of a project. For example, construction professionals can propose the lower cost alternatives for architectural design, construction methods, construction materials, and long-term maintenance, while maintaining the quality and feasibility of the establishment. The cut expenses can be reallocated or saved for further use. - Quality Enhancement

Value engineering allows an overall quality improvement of a project. When it comes to value engineering, engineers not only look for ways to accomplish the intended design but to improve it as well. When the unnecessary expenses are cut out, the fund may be reallocated to improve the quality of the project. - Efficiency Optimization

Through systematic approach, every feature of a build is analyzed and multiple alternatives are evaluated in the early planning stage. The best design alternatives can be determined and the cost/ time schedule can be finalized at the early stage. When it happens to have circumstances and delays during construction, the engineer has alternative ways to get a project back on track. This can increase efficiency and make sure the project is on schedule. - Creativity

The proposal of value engineering is often the outcome of brainstorming with a team of experts, from engineers and architects to quantity surveyors. It is the multidisciplinary effort of the team members who work together in creative design, analysis, evaluation, and development processes. Problems identification is done at an early stage with proposed solutions to avoid critical mistakes during the construction phase. Through their findings, the value of a project can be enhanced, thus increasing the satisfaction and confidence of clients.

THE STAGES OF VALUE ENGINEERING

There are three stages in the value engineering process:

- Planning phase

In the planning phase, value engineering focuses more on collecting information and identifying the problem of the project. In the early stage of planning, engineers should decide if they want to employ value engineering in a project. If yes, they must be ready to come out with alternative designs and construction methods along with alternative materials to provide the best value to their clients. Besides, engineers will involve in the concept of life cycle cost in the planning phase to have a better understanding of a project in various stages. - Design phase

In the design phase, value engineering focuses more on exploring alternative designs and finally comes out with the most economical, yet structurally-sound options. By employing value engineering in the design phase, engineers can avoid some critical mistakes in the construction phase. For instance, the mechanical, electrical, and plumbing (MEP) systems clash is one of the common mistakes during construction. Hence, while designing MEP systems, reliability offers the greatest value. It can be achieved by using intelligence-based, computer-aided design (CAD) tools such as BIM software. - Construction phase

In the construction phase, the focus is more on accomplishing the required tasks at the lowest cost. Usually, if contractors have good construction scheduling and enough manpower, downtime and unproductive tasks can be reduced. Besides, an additional saving can be found by using experienced contractors who can provide in-field solutions that increase the value of a project.

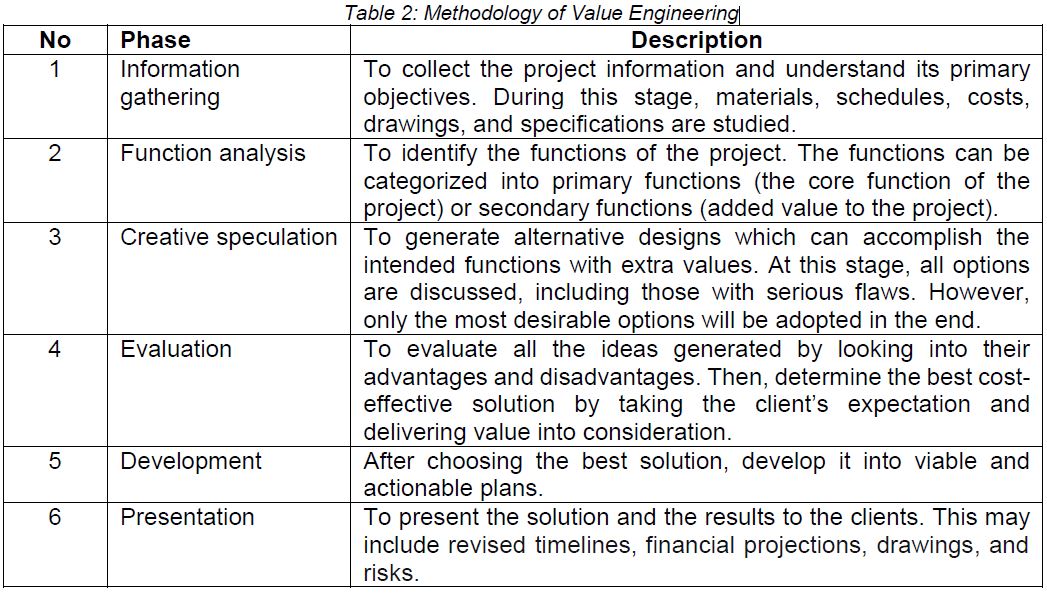

METHODOLOGY OF VALUE ENGINEERING

Generally, value engineering is conducted in a formal and systematic way. It consists of 6 phases which are information gathering, function analysis, creative speculation, evaluation, development, and presentation [3]:

CHALLENGES OF IMPLEMENTING VALUE ENGINEERING

- Maintain the project schedule

By implementing value engineering, engineers will explore alternative solutions instead of conventional and straightforward solutions to increase the value of a project. However, by doing so, it will need extra time for research purposes, and this may slow down the project. - Maintain product quality

One of the easiest ways to cut the cost of a project is by reducing the quality of the product, therefore, some clients will ask engineers to do so. Thus, engineers shall convince clients to maintain project qualities to ensure the safety of users, at the same time look for the alternative that can increase the project value while retaining the quality. - Getting everyone on board

Communication is the key to implementing value engineering successfully. If everyone understands the need to make changes, then it will be easier. However, sometimes different people will have different perspectives and pleasing everyone could be difficult, thus further explanation is needed. Therefore, this is a real challenge for the team leader to get everyone on board.

CONCLUSION

In a nutshell, value engineering innovates on alternative solutions that can ultimately reduce the construction or even operation cost burden to the developer and end user while maintaining quality. A properly managed value engineering should be beneficial to all stakeholders and is proven to be effective when cost viability becomes a concern to the stakeholder.

Ir. Dr. Justin LAI Woon Fatt

CEO/ Founder

IPM Group

References:

[1] Surbhi S. (2022, March 17). Difference Between Value Analysis and Value Engineering. Key Differences. Retrieved on 31st March 2023 from https://keydifferences.com/difference-between-value-analysis-and-value-engineering.html

[2] FDC. (n.d.) (2022, February 22). The Benefits of Value Engineering in Commercial Construction. Retrieved on 31st March 2023 from https://fdc-comp.com/value-engineering-commercial-construction/

[3] Bernie Roseke (2020, March). The 6 Steps of a Value Analysis. Retrieved on 31st March 2023 from https://www.projectengineer.net/the-6-steps-of-a-value-analysis/