Author: Ir. Dr. Justin LAI Woon Fatt | 17 October, 2024

INTRODUCTION

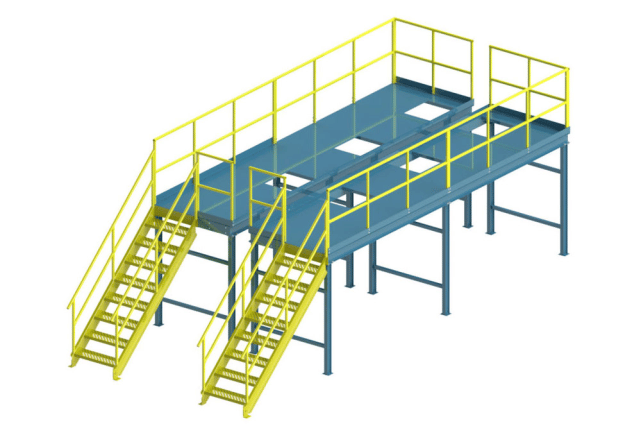

In general, a steel platform is a flat, elevated surface used for a variety of purposes that is supported by a structural framework mainly composed of steel. Typically, it is made of columns, primary and secondary beams, ladders, railings, and planks. Small components like rivets, screws, or welds are used to join the gaps between each steel member [1]. Due to its robustness, durability, and versatility, these platforms are vital parts of numerous kinds of industries. In contemporary industrial production, steel structure platforms are frequently used in petrochemical, metal smelting, and other mining industrial operations [2]. The steel structure platform can be produced and designed to satisfy site requirements, functional needs, and logistics requirements because it is a completely assembled structure with versatile designs [1]. To ensure durability and productivity, numerous structural and safety considerations must be carefully taken into account during the platform’s design.

STRUCTURAL DESIGN FOR STEEL PLATFORM

1. Purpose and Requirements

The desired usage of the platform must be clearly defined before any design work takes place. The particular demands will determine the design specifications and requirements, whether they are intended for storage, equipment support, or personnel access. This includes load capacity, environmental factors, and any applicable regulatory requirements.

2. Load Analysis

A thorough load analysis is crucial. This includes dead loads (weight of the structure itself, permanent fixtures such as plumbing or electrical wiring, flooring materials (wooden planks), live loads (occupants, equipment, and machinery), and environmental loads (wind, snow, and seismic activity). Several design codes, such as those from the British Standards (BS), American Institute of Steel Construction (AISC), or Eurocodes provide the guidelines for determining these loads and ensuring the platform can safely support them.

3. Material Selection

Steel is widely utilized because of its robustness, durability, and versatility. Choosing appropriate steel grade is crucial for ensuring strength and durability. Commonly used steels include structural steel grades like S275 and S355 [4]. The selection depends on the factors such as load requirements, environmental conditions, and potential exposure to corrosive elements. Anti-corrosive coatings may also be taken into consideration to increase lifespan and save maintenance costs, particularly for platforms situated in hostile environments.

4. Structural Analysis and Design

Structural analysis involves modelling the platform to predict how it will respond to applied loads. Engineers use various methods, such as the Finite Element Method (FEM) to simulate and compute structure’s deformations, internal forces, support reactions, and identify stress points. The design must ensure that all components, such as beams, columns, and connections, are adequately sized and reinforced to handle the calculated loads. Proper design also involves optimizing the use of materials to balance cost and performance.

The design of steel platforms typically follows established principles:

- Framework Design: Platforms often utilize a grid framework for stability, incorporating beams and columns to distribute loads efficiently.

- Connection Design: Connections between steel components must be adequately designed to ensure structural integrity. Welded and bolted connections are commonly used connections, and their strength is critical in maintaining overall stability.

- Deflection and Vibration Control: Ensuring that deflections and vibrations are within acceptable limits is essential for safety and comfort, particularly for platforms that support machinery or large groups of people.

5. Safety and Compliance

Safety is paramount in platform design. Hence, compliance with safety standards and regulations is essential. This includes adhering to the codes for structural integrity, load capacities, and safety features. The safety design incorporates guardrails and safety barriers to prevent falls. Besides that, the access and egress should designed to facilitate personnel’s safety including staircases and emergency exits. In brief, safety codes like OSHA (Occupational Safety and Health Administration) regulations or similar standards outline the requirements for worker safety and platform design.

CONCLUSION

In conclusion, steel structure platforms are designed to optimize building layouts, improve space utilization, and provide support for production activities, making them essential in factories and warehouses. A comprehensive design approach is crucial, balancing structural integrity, safety, and practicality. Failure to meet design requirements may lead to instability, accidents, user discomfort experience, and reduced productivity. By clearly understanding the purposes, conducting load analysis, selecting the suitable materials, and adhering to safety standards, engineers can ensure that these platforms are robust and fit for their designated use.

Ir. Dr. Justin LAI Woon Fatt

CEO/ Founder

IPM Group

References:

[1] Steel Structure Working Platform. (n.d.). Havit Steel Structure. Retrieved on 17th October 2024 from https://www.steelbuildingstructure.com/steel-structure-working-platform/

[2] Steel Structure Platform Design (n.d.). K-Home. Retrieved on 17th October 2024 from https://khomesteel.com/application-of-steel-structure-platform.html

[3] Steel Platform Manufacturer. (n.d.) Sunnyda Professional Housing Manufacturer. Retrieved on 17th October 2024 from https://www.sunnyda-house.com/steel-platform/

[4] Gilbert. N. (2012). Structural Steel – S235, S275, S355 Chemical Composition, Mechanical Properties and Common Applications. Retrieved on 17th October 2024 from https://www.azom.com/article.aspx?ArticleID=6022