Author: Ir. Dr. Justin LAI Woon Fatt | 22 December, 2019

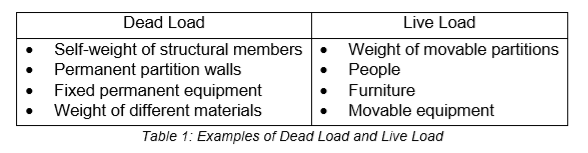

A structure should be capable of withstanding the most severe combination of forces that are likely to be applied to it. The combination of forces includes dead load and live load. Different structures will be subjected to different amounts of loadings as the intended purposes of the buildings are different. For example, compared to an industrial building where there would be heavy machinery, a floor slab in an office building would be designed to have a lower load capacity.

The strength of a floor slab is mainly defined by the type and quantity of materials used to form it. Altering the composition will result in different tolerable ultimate load combinations in the slab. However, slabs that are made usually do not have the same actual load capacity as predicted for the design load capacity. This is caused by several factors:

- Poor workmanship

- Poor mixture of concrete

- Lack of compliance with relevant standard procedures

- Poor joint design

- Early removal of formwork

- Poor construction supervision

Two general ways to determine the loading of the floor slab, which are:

i. Knowing The Design Load Capacity From The Drawing

The design load capacity is the planned capacity specifically used for design purposes. From the engineering drawings, specifications of the floor slabs such as the concrete thickness, concrete grade, and diameter of reinforcement bars can be known. Based on this information, a reversed calculation can be carried out to determine the design load capacity of the floor. However, there might be some discrepancies between the actual capacity and the design specifications. The reliability of the calculated load capacity may be lower as it does not account for factors such as the amount of compaction of the concrete or the amount of material used.

ii. Knowing The Actual Load Capacity By Doing Lab Test

The actual load capacity is the load capacity on the structural member upon completion of construction. A lab test is encouraged to be carried out to find out the actual specification of the floor slab. By doing coring, the same specification (concrete thickness, concrete grade, and the diameter of reinforcement bars) can be known and the actual load capacity of the slab can be justified by reversed calculation. The reliability is relatively higher as all the material specification had been proven.

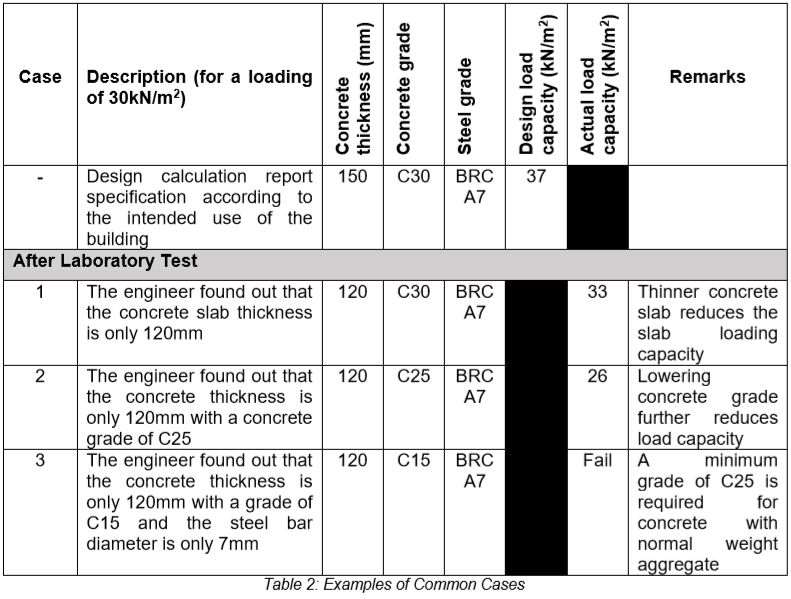

Here are some common cases for references:

Consequences of Using a Low Capacity Floor Slab

It is critical to identify the actual load capacity of the floor slab before installing heavy machinery, platforms, racking system, etc. for production. Placing a load heavier than the allowable load slab capacity will cause slab overloading and subsequently cause cracking. When cracks are formed, all equipment or load installed on top of the slab must be removed for concrete repairing. The impacts of this issue are not only incurring additional costs for repairing and dismantling or uninstalling existing equipment/machinery, but also causing production delays which result in slow deliveries and customers claiming for the losses.

Conclusion

Due to there will always be discrepancies between the design load capacity and the actual load capacity, thus it is crucial to consult a qualified professional engineer to identify the actual load capacity of the floor slab. Consulting a professional engineer beforehand will help to identify any existing problems and prevent any unnecessary costs.

Ir. Dr. Justin LAI Woon Fatt

CEO/ Founder

IPM Group

Reference:

[1] Mishra,G. (2019). Strengthening Techniques- R.C. Slab. The Constructor Civil Engineering Home. Retrieved on 11 September 2019 from https://theconstructor.org/structural-engg/strengthening-techniques-r-c-slab/1921/.