Author: LAU Yeo Shin | 23 September, 2019

Ever wonder if you need to abandon the entire building after fire outbreak? Or you think the building is safe for reuse after you replaced the damaged furniture?

There are two types of fire damage generally, namely architectural damage and structural damage. Architecture damage is directly visible. Examples for architecture damage are broken glass, burnt wooden furniture, paint spalling, smoke stain, melted wire, etc. There would be little doubt for most building owners that these damages have to be fixed or repaired before they could reoccupy the building. On the other hand, structural damage may not always intuitive and visible with mere visual observation. It is always required/ encouraged to appoint an experienced engineer to inspect the burnt buildings before the owners decide to reoccupy them.

While fire temperature varies depending on the type of fuel, environmental factor and location across the building, an ambient temperature ranging between 600 degrees Celsius and 1000 degrees Celsius is reasonably expected in a fire outbreak. Concrete and steel being two main structural materials in modern construction undergo notable deterioration in their mechanical properties under elevated temperature albeit they sometimes appear to be in good condition after fire. The compressive strength of concrete reduces to approximately 60% of its original strength at 600 degrees Celsius and approximately 20% at 800 degrees Celsius. Similar to compressive strength reduction, concrete generally experiences 20% reduction of its initial tensile strength at 300 degrees Celsius and the reduction will further increase to 80% at 600 degrees Celsius. The decrease in concrete compressive strength reduces the overall load taking capacity of concrete members while the decrease of concrete tensile strength promotes the formation and propagation of microcracks and eventually leads to concrete spalling. The inner layer of concrete and reinforcement bars are exposed directly to fire after the surface concrete spalls, hence, leading to a faster reduction rate and depth of concrete strength. As opposed to concrete spalling which can be identified easily through visual inspection, reduction of concrete strength exhibit very little to no visual indication (pink/red discolouration of concrete could be used as a reasonable indication of concrete strength reduction but such discolouration may not always apparent to the inspector) and its determination often requires in situ tests or site sampling for laboratory tests.

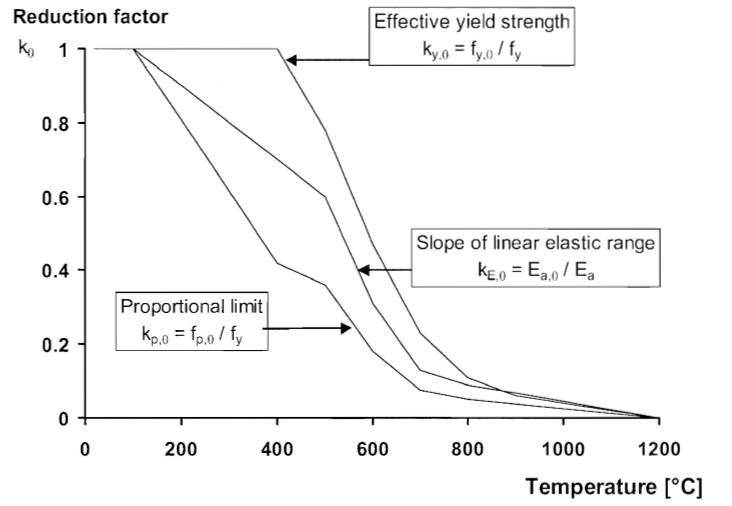

As for structural steel, Eurocode 3 Part 1-2 has specified a constant yield strength up to 400 degrees Celsius and decreases rapidly afterward with 22% reduction at 500 degrees Celsius, 53% reduction at 600 degrees Celsius and 77% reduction at 700 degrees Celsius as illustrated in the figure shown below. Yield strength reduction at elevated temperature promotes earlier occurrence of steel member buckling which is otherwise prevented at room temperature. Besides, reduced yield strength also forced steel members to undergo unrecoverable plastic deformation (unless by heat straightening in limited applications done by experienced personnel) which is why extraordinary deformation is always observed on steel members after most fire incidents. Various tests can be deployed to determine the extent of fire damage to steel members in combination with visual inspection. In cases and regions where steel exposure to fire is less extreme, reusing the steel members with or without further strengthening could be possible after verifications by an experienced engineer.

Figure 1: Reduction factor for effective yield strength, proportional limit and Young’s Modulus at elevated temperature (abstracted from BS EN 1993-1-2:2005)

Figure 1: Reduction factor for effective yield strength, proportional limit and Young’s Modulus at elevated temperature (abstracted from BS EN 1993-1-2:2005)

Happy doesn’t always go lucky, rather than wishing for the best, it is always recommended that property owners should engage competent engineer to review the structural safety of existing building whenever there happens a fire outbreak in their properties. The same is encouraged for the owners of adjacent properties who consider or doubt if their buildings are significantly impacted by the adjacent fire. In fact, IPM has come across situations where properties adjacent to a burnt building experienced structural damage after fire. Sample photos for fire damage from previous projects are provided below for further illustration.

Figure 2: Steel roof truss damage under elevated temperature

Figure 2: Steel roof truss damage under elevated temperature

Figure 3: Steel roof truss and platform damage under elevated temperature

Figure 3: Steel roof truss and platform damage under elevated temperature

Figure 4: Concrete spalling at column under elevated temperature

Figure 4: Concrete spalling at column under elevated temperature

Figure 5: Structural cracks discovered on concrete column after removing party wall for inspection

Figure 5: Structural cracks discovered on concrete column after removing party wall for inspection

Structural repair if necessary upon the assessment by competent engineer can be done at the lowest cost during the rehabilitation period. In most scenarios, the remedy cost is considerably higher if temporary shutdown for repair in later stage is required when the structural damage gets worse over time and becomes visible to the property owner. Prevention is better than cure, timely “treatment” would be a wise decision.

LAU Yeo Shin

Partner

IPM Professional Services Sdn Bhd

References:

[1] Venkatesh Kodur, “Properties of Concrete at Elevated Temperatures,” ISRN Civil Engineering, vol. 2014, Article ID 468510, 15 pages, 2014. https://doi.org/10.1155/2014/468510.

[2] EN 1993-1-2 (2005) (English): Eurocode 3: Design of Steel Structures – Part 1-2: General Rules – Structural Fire Design